LUXOR PRESS - SR 862 - Ceramic Furnace

The SR 862 "Luxor Press" is a fornace suitable for ceramics obtained through "Press-injection" after having heated the solid ceramic up to its plastic status. The ceramic injection process is done through a mechanism operated by compressed air.

The SR 862 "Luxor Press" is a fornace suitable for ceramics obtained through "Press-injection" after having heated the solid ceramic up to its plastic status. The ceramic injection process is done through a mechanism operated by compressed air.

The injection pressure can be regulated with a manual pressure regulator, supplied with a manometer for the visualisation. The fornace must be therefore connected to the air compressed system of the laboratory or a compressor.

In the firing cycle all variables related to Press-injection can be set, the fornace is therefore suitable to fire all types of ceramic. Furthermore, the SR860 Luxor Press is also suitable to fire all types of normal ceramic, which means a full time utilization of the fornace in dental laboratories.

The electronic control manages 80 programmes for the firing of "normal" ceramics and 20 programmes for "Press-injection".

Technical Specifications: |

SR 862 |

| Power Supply | 230 V - 50/60 Hz |

| Power (no pump) | 1200 W |

| Fuses | 10 A |

| Dimensions | 40 (L) x 44 (P) x 50 (H) cm |

| Weight | 30 Kg |

| Available programmes | 100 |

| Functions (variables) per normal ceramic programme | 15 |

| Functions (variables) per injection ceramic programme | 14 |

| Selfcalibration programme | SI |

Accessories:

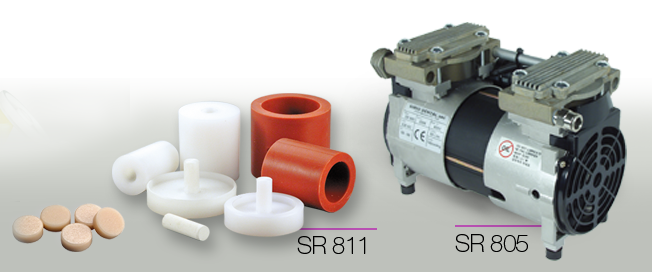

SR 811 Kit standard for up 5 element press

Setting variables per cycle:

| F 1 | ta | Drying Temperature (or starting temperature) from 20° to 1200° Celsius. This temperature is obtained with a fixed slawe rate of 70°C/min |

| F 2 | t1 | Drying Time or Muffle closing time (minutes and seconds). Once the Drying Temperature TA is reached, the plate will lift itself and according to the set value of this variable will close the muffle |

| F 3 | t3 | Drying Time with closed muffle before the firing begins (in minutes and seconds). This time can be important to balance the inner muffle temperature after this has closed. If you set 0, after having closed the muffle the oven will start immediately the heating of the following phase F4 |

| F 4 | TC | Firing Temperature from 20° up to 1200°C |

| F 5 | VC | Slawe rate (in °C/min.) It varies from 2 to 200°C/min |

| F 6 | tc | Firing time (in minutes and seconds) |

| F 7 | Vacuum | (1=YES, 0=NO) |

| F 8 | tv-on | Starting temperatures of the vacuum pump. The vacuum can be set during the firing phase: therefore TV-ON must be higher or the same as TA |

| F 9 | tv-off | Off temperature of the vacuum pump. It can be lower or the same as TC |

| F 10 | tv-off | Lasting time of the vacuum to the TC. This value must be set only in this case TV-OFF=TC |

| F 11 | %V | Vacuum level expressed in % of the absolute vacuum |

| F 12 | TR | Guided cooling up to the pre-set temperature. The oven will cool slowly with a the cooling speed set in F13 before starting to open the muffle |

| F 13 | vr | Cooling speed in C°/min during the slow cooling |

| F 14 | t3 | Muffle opening time (in minutes and seconds). If you set the value 0 the muffle will automatically open |

| F15 |

tf | Final Temperature: it is the temperature the oven has been pre-set at the end of the cycle. This value will be set depending on the cooling temperature of the next cycle |

Setting variables per cycle Press Ceramic:

| F 1 | T1 | Start Temperature: it is the temperature from which a press-injection cycle starts. When you start the programme the oven raises its inner Temperature up to the T1. When such temperature is reached the oven will give a sound signal to indicate that it is ready for the cylinder. The user must open manually the oven, place the cylinder, close again the oven with the arrows and the cycle will continue |

| F 2 | t 2 | Injection temperature: it is the Temperature the oven will reach to obtain the softening of the “rough” and proceed with the injection |

| F 3 | Vs | Slawe rate expressed in C°/min: it indicates the increase of temperature the oven uses during the heating from T1 to T2 |

| F 4 | tm | Holding Time: it indicates the time the oven keeps the temperature T2 before the injection. This time varies from 10 to 20 minutes depending on the type of ceramic and the selected T2 temperature |

| Fp | pi | Injection Pressure. It represents the compressed air the technician wants to use during the injection. By increasing the pressure also the driving force on the material to be pressed will increase |

| Ft | ts | Pressure Ramp. It represents the time used to reach the chosen pressure. The pressure is not reached all at once but slowly according to the time chosen in this variable. |

| F 5 | tl | Injection time: it indicates the time, after the injection, that the oven will keep the pressure on the ceramic in order to obtain the completion of the pressure firing. This time is of about few minutes (normally about 5 minutes) |

| F 6 | tp | Post-injection time: it indicates the time the oven will maintain the temperature T2 after having released the pressure. This function is not used for many types of ceramics, if this is the case set the value F6 = 0 |

| F 7 | Vacuum | YES (It is impossible to set cycles without vacuum) |

| F 8 | tv | Starting vacuum Temperature: it indicates the temperature the pump goes On. The vacuum stops at the end of phase F4, that is when the pressure is released unless a different value from 0 is set for the variable F10 |

| F 9 | Vacuum Level | A vacuum level in percentage to the absolute level can be set. It is suggested to set the value at 95% |

| F 10 | Tpv | Post-injection vacuum time: if a different value from 0 has been set at the variable F6, the vacuum can be kept during this time. For most ceramics this value must be 0 |

| F 11 | Tr | Guided cooling up to: it indicates the temperature the oven will reach during the cooling with a closed muffle |

| F 12 | Vd | Drop speed: during the cooling set in variable F11 also set the cooling drop in °C/min |

| F 13 | ta | Muffle opening time: the muffle will slowly open in steps according to the time set in this function |

| F 14 | Tf | Final Temperature: it indicates the temperature the oven will remain once completed the cycle. This temperature is set according to the following cycle |